利用生菜瞬时表达蛋白需要通过将目标基因插入植物表达载体,但不需要建立稳定表达蛋白的纯合品系。在对生菜叶片进行侵染后四天内即可获得表达目标蛋白的生菜表,之后将生菜叶进行收获,经过蛋白提取和纯化过程,即可获得高纯度的目标蛋白。

The use of lettuce to express proteins instantaneously requires the insertion of the target gene into the plant expression vector, but does not require the establishment of a homozygous strain that stably expresses the protein. In the four days after the infestation of lettuce leaves, the lettuce table expressing the target protein was obtained, and the lettuce leaves were harvested. After the protein extraction and purification process, the target protein with high purity could be obtained.

1)单株生菜蛋白生产量高:惠升专有平台技术使生菜瞬时生产外源蛋白量提高到了1.67g/kg,是目前所知瞬间生产系统最高的生产量;

2)侵染效率高:整株生菜的侵染阳性率的提高到了90%以上,而其他技术侵染效率只有不到50%。

1) High yield of single lettuce protein: high-yield platform technology to make lettuce instantaneous production of foreign protein increased to 1.67g / kg, is now known instantaneous production system the highest production capacity;

2) High efficiency of infection: the positive rate of whole plant lettuce infection increased to more than 90%, while other technology infection efficiency of less than 50%.

对比传统植物分子医药1-2年的研发周期,惠升利用专有平台技术,在短短4天内就能获得目标蛋白质进行功能检测,大大缩短了产品开发时间,研发可持续性强。

Compared with the traditional plant molecularmedicine1-2 years of research and development cycle, the use of proprietary platform technology, in just 4 days will be able to obtain the target protein for functional testing, greatly reducing the product development time, research and development sustainability.

生菜生长周期仅为35天,且种植占地面积小,可实现封闭式管理,无土栽培,全年无限量供应。

Lettuce growth cycle is only 35 days, and planting covers an area of small, can be closed management, soilless cultivation, unlimited supply throughout the year.

解决植物种植均一性问题: 建立自动化生产流水线,并结合育种技术与自动化播种、种植、灌溉和挑选采摘为一体的植物工厂,能保证原料的高度一致性。排除植物在种植过程中受外界污染的可能:对比传统原料种植大都采用全开放式或半开放式的方式,我们的规模化种植将采取全封闭式、无土、无菌栽培,从源头上解决病虫害、动植物病毒、细菌、重金属和农药残留等问题。

To solve the plant planting homogeneity problem: to establish an automated production line, combined with breeding technology and automated sowing, planting, irrigation and picking as one of the plant plant, to ensure a high degree of consistency of raw materials.

Eliminate the possibility of contaminated plants in the process of planting: the traditional use of traditional raw materials are mostly open or semi-open way, our large-scale cultivation will be fully enclosed, soilless, aseptic cultivation, from the source to solve Pests and diseases, animal and plant viruses, bacteria, heavy metals and pesticide residues and other issues.

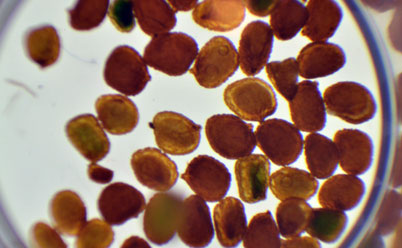

将目标蛋白表达在植物种子中,人们可以通过种植此类植物来获得制造目标蛋白的原材料,为大规模生产和储运此类蛋白创造了条件。惠升将用此平台技术生产蚓激酶、阿替普酶 (t-PA)、替奈普酶(TNKase)、瑞替普酶(rt-PA)等溶血酶。

Expression of the target protein in plant seeds, people can plant such plants to obtain the target protein to produce raw materials for large-scale production and storage and transportation of such proteins to create the conditions. Hui Sheng will use this platform technology to produce lumbrokinase, alteplase (T-PA), TNKase, rituximab (rt-PA) and other hemolytic enzymes.

以阿替普酶(t-PA)为例,惠升生物采用专有平台技术,每亩转基因水稻可以生产出价值180 亿元的t-PA,供180万名急性缺血性脑卒中病人或者心血管病人使用。

To alteplase (t-PA), for example, Hui Sheng biological using proprietary platform technology, per acre of transgenic rice can produce 18 billion yuan worth of t-PA, for 1.8 million patients with acute ischemic stroke or Cardiovascular patients use.

以阿替普酶(t-PA)为例,转基因水稻种子易于保存和运输,储运要求大大降低。

To alteplase (t-PA), for example, transgenic rice seeds easy to save and transport, storage and transportation requirements greatly reduced.